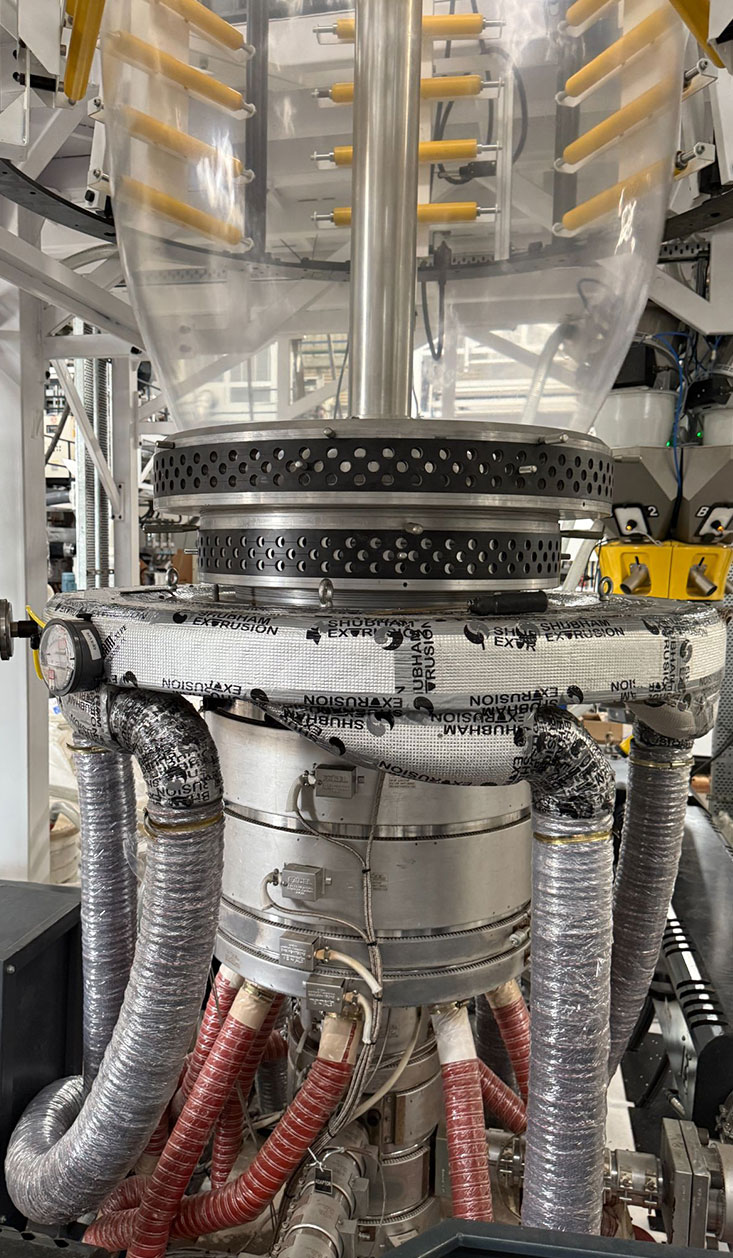

Take your packaging capabilities to the next level with Shubham Extrusion’s advanced Stretch Film Extrusion Technology. Engineered for high-speed, multi-layer, and energy-efficient film production, our extruders help manufacturers produce strong, clear, and stretchable films that meet modern industry standards.

With over 27+ years of experience and thousands of successful installations worldwide, Shubham is your trusted partner in film extrusion technology.

Uncompromising Quality: Precision-engineered components deliver optimal performance and reliability.

Tailor-Made Configuration: Fully customizable to suit your specific application and production requirements.

Connect for Stretch Film Extruders Connect for Stretch Film ExtrudersDelivers up to 180–330 kg/hr, ensuring fast ROI and meeting bulk order demands.

Supports a wide range of materials like LL/LDPE, HM/HDPE, EVA, Metallocene – even biodegradable options.

Produces film between 20–200 microns with layflat widths from 1200–2100 mm for various packaging formats.

Optimized for reduced energy consumption, minimized material waste, and low maintenance.

Built with Japanese steel die heads, plasma-nitrided screws, and force-cooled gearboxes for long life.

Blown film's manufacturing process, results in a film that is more resistant to punctures and tears. This makes it ideal for wrapping pallets with sharp or irregular objects.

Blown film's memory and elasticity allow it to stretch and tighten around the load, providing a secure hold during transportation.

Due to its strength and durability, blown film is the preferred choice for wrapping heavy or bulky items.

Our stretch film extrusion machines are trusted across sectors:

Surface Protection Film

Shrink Hood Film

Lamination Film

Mattress Cover Films

Tarpaulin Films

Stretch Film Rolls

LDPE Shrink Film

Courier Bags

Atta & Milk Packaging

Food Wrapping Films

Mulch films

Agroshed net films

From pallet wrapping to product protection, our films ensure secure, economical, and reliable packaging solutions.

| Parameter | Details |

|---|---|

| Polymer Compatibility | LL/LDPE, HM/HDPE, EVA, Metallocene |

| Thickness Range | 20–200 µm |

| Layflat Range | 1200–2100 mm |

| Output Capacity | 180–330 kg/hr |

| Film Layers | 3-layer co-extruded (A-B-A structure) |

- Global Expertise: 3500+ successful installations in over 67 countries

- Innovative Engineering: Industry-first IBC die head tech for uniform film

- Reliable Support: Training, smart remote diagnostics & rapid field service

- Proven ROI: Engineered for cost savings, film consistency & fast returns